| Sign In | Join Free | My esadidasol.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My esadidasol.com |

|

Brand Name : YDobot

Model Number : EWR-YJ10

Certification : ul

Place of Origin : china

MOQ : 1

Supply Ability : 500sets/month

Packaging Details : carton ➕ Foam inner packaging, outer frame fixed by wood frame

Core Components : PLC, Motor

Weight : 40kg

Axis : 6 axis

Payload : 10kg

Reach : 1300mm

Key Words : Loading Unloading Avoid Obstacles 10kg

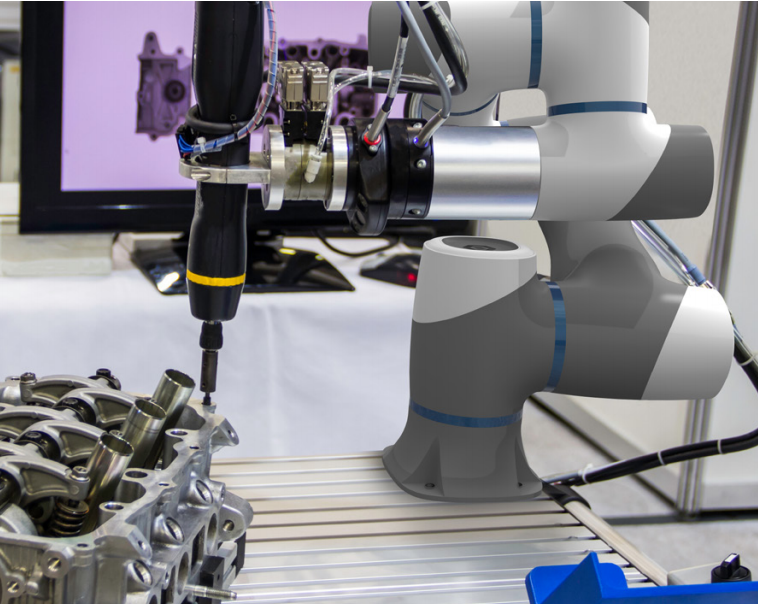

Cooperative robot with 10kg load for loading and unloading can actively avoid obstacles

Product Advantages

Main Porduct

ABB Robot Arm

Kuka Robot Arm

Robot Tank Trucks

| ITEM | VALUE |

| Applicable Industries | Library, sample workshop, hotel, clothing store, building materials store, machinery repair shop, manufacturing factory, food and beverage factory, farm, restaurant, household, retail, food store, printing shop, construction engineering, energy and mining, food and beverage store, advertising company, others |

| After Warranty Service | Video technical support, Online support |

| Local Service Location | None |

| Showroom Location | None |

| Video outgoing-inspection | Provided |

| Machinery Test Report | Provided |

| Marketing Type | New Product 2020 |

| Warranty of core components | 1 Year |

| Core Components | PLC, Motor |

| Place of Origin | China |

| Brand Name | DOBOT |

| Weight | 40kg |

| Warranty | 1 Year |

| Technical service | Online support |

| Weight (KG) | 40kg |

| Brand | DOBOT |

| Axis | 6 axis |

| Payload | 10kg |

| Reach | 1300mm |

| Rated voltage | DC48V |

| Maximum operating speed | 4m/s |

| Repeatability | ±0.03mm |

| IP protection | IP54 |

| Temperature range | 0~45° |

| Typical power consumption | 350W |

Customer pain points:

Formaldehyde, acetaldehyde and other harmful gases exist in the plasticizing workshop, which is not conducive to human health.

Manual feeding is inefficient and easy to cause unexpected risks.

Solution:

After getting the labeled materials through the CR10 robot, the high-speed conveyor belt will send the materials to the limit block, and the eccentric gripper will move the mechanical arm to the barrel edge. The soft coating material will be used to achieve the action of sticking the injection molding surface materials to the stickers, thus realizing the process requirements of fully automated assembly line production.

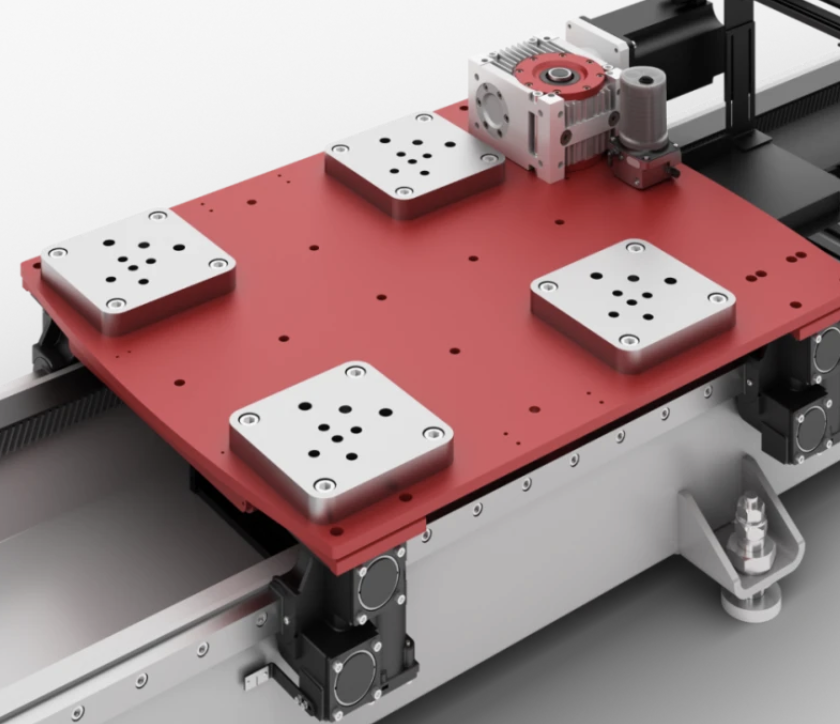

Our company can also configure robots with peripheral products, such as guides, turntables, protective clothing, and pipe packages

If you have any questions, please feel free to contact us at WhatsApp:+8618601676399 Email: carmen.lu@rely-robot.com

Our logistics and packaging methods

|

|

fanuc collaborative robotic arm 10kg 6 Axis Loading Unloading Avoid Obstacles Images |